Silk Screen 4 Color Process Density Reading

There are different levels of procedure control that are used for print. While visual comparisons can exist used to provide a rudimentary judgment of a lucifer, they can be very subjective, and thus non very accurate, or repeatable.

Using a densitometer can provide quantitative actionable feedback for the printing operator. This can include measurements of solid ink density, tone value increase (also known equally dot gain), Ink Trap, and other impress characteristics. These are known as mechanical impress characteristics. That ways that we are measuring changes as a outcome of a mechanical change on printing. For example, a alter in ink density can be a direct consequence of the alter of ink picture thickness or volume that is practical. A change in dot proceeds tin be a effect of a modify in impression pressure or the coating and packing status. Ink trap is a measure of how well an ink transfers to a substrate with a previous ink practical.

Monitoring all of these mechanical print characteristics is a good foundation to process command and especially critical for the consequent reproduction of continuous tone images and graphics.

What is Density Measurement?

First, it is of import to understand that density is not color. Density only represents how low-cal or nighttime the color is, but not if the color is right. For example, if an ink is contaminated, and the colour has shifted, you may still exist able to attain the correct density value, but the colour will appear unlike. If yous need to confirm that the colour is correct, such as to match a specified L*a*b* value, you will need to use a spectrophotometer.

Allow'southward take a look at the types of measurements that you can use to control density on printing with a densitometer. First, we will look at four-color procedure control, and so spot color ink control.

i - Iv-Color Procedure Control

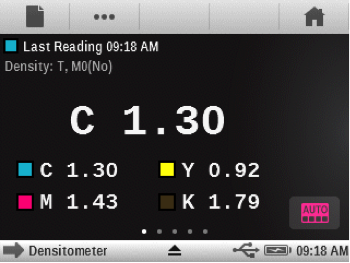

Density is the near basic measurement of the mechanical characteristics of print. Reflective density is calculated from the corporeality of light that is reflected from the substrate (paper, movie, etc.) and the ink. It is a simple way to evaluate changes in the ink film thickness or ink concentration that is being laid down. Every bit ink thickness or concentration increases, more than light is absorbed, and less light is reflected, so the instrument reports the darker advent as higher density.

Density is the near basic measurement of the mechanical characteristics of print. Reflective density is calculated from the corporeality of light that is reflected from the substrate (paper, movie, etc.) and the ink. It is a simple way to evaluate changes in the ink film thickness or ink concentration that is being laid down. Every bit ink thickness or concentration increases, more than light is absorbed, and less light is reflected, so the instrument reports the darker advent as higher density.

On an kickoff printing, the ink pigment load is very consequent, so a change in density is directly correlated with a change in ink flick thickness. On a flexographic press, the ink load may change with concentration of the ink. The improver of extender or water to flexographic ink volition result in less ink pigment transferring to the substrate, and this will be lighter, with a lower density value. With evaporation of the ink carriers, the flexographic ink concentration volition increase, and measure out as a higher density. Using the density values of the Cyan, Magenta, Xanthous and Blackness solid inks to monitor and correct the ink film thickness or concentration is cardinal to printing control.

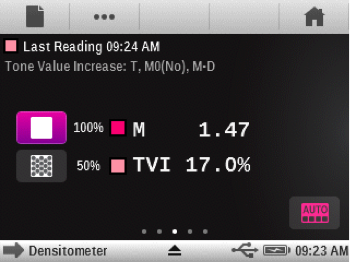

Tone Value is likewise known as dot surface area. This is the measurement of printed screen tint values. It is conveyed every bit a percentage of the solid ink density. Tone value increase (TVI) is also commonly known equally dot proceeds. TVI represents the difference between the printed tone value, and the tone value in the original file. For instance, if a control patch for the 50% tint is measured, and the result is a tone value of 68%, then the tone value increase is 18%. Depending on your print process and press scale method, typical normal CMYK TVI values range from 16-22%.

Tone Value is likewise known as dot surface area. This is the measurement of printed screen tint values. It is conveyed every bit a percentage of the solid ink density. Tone value increase (TVI) is also commonly known equally dot proceeds. TVI represents the difference between the printed tone value, and the tone value in the original file. For instance, if a control patch for the 50% tint is measured, and the result is a tone value of 68%, then the tone value increase is 18%. Depending on your print process and press scale method, typical normal CMYK TVI values range from 16-22%.

Some would argue that for images, the tone value is more than important than the solid ink density. Images and many graphics are made upward from screen tints. In these cases, there is no solid ink within these areas. If the TVI is as well high in all of the procedure colors the images will exist too dark. Even worse, if the TVI is likewise high in some of the process colors and lower in others, the image will have an undesirable shift in color balance.

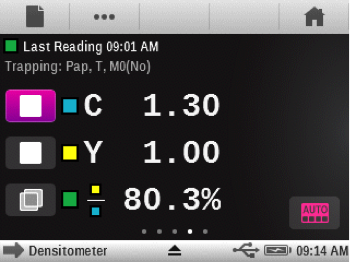

Ink Trap (more than accurately apparent trap) is a measure of how well a wet ink will transfer to the substrate and the previous ink in the printing sequence. Higher trap percentages are better. While in that location is no specific standard for this, it is generally desirable to attain lxxx% trap or better. This may be easier to achieve on a press with dryers in between the ink stations, like many flexographic presses, and more difficult on a press that does not, similar about offset presses. Measuring trap is a style to predict a color shift in your overprint colors. Consider an paradigm with aredmotorcar on agreenish lawnand ablue heaven. Poor trapping characteristics will go far difficult to achieve and maintain a color match of both theblue sky(Cyan and Magenta) andgreengrass (Cyan and Yellow).

Ink Trap (more than accurately apparent trap) is a measure of how well a wet ink will transfer to the substrate and the previous ink in the printing sequence. Higher trap percentages are better. While in that location is no specific standard for this, it is generally desirable to attain lxxx% trap or better. This may be easier to achieve on a press with dryers in between the ink stations, like many flexographic presses, and more difficult on a press that does not, similar about offset presses. Measuring trap is a style to predict a color shift in your overprint colors. Consider an paradigm with aredmotorcar on agreenish lawnand ablue heaven. Poor trapping characteristics will go far difficult to achieve and maintain a color match of both theblue sky(Cyan and Magenta) andgreengrass (Cyan and Yellow).

Even so, the printing conditions may limit the ability to accomplish proficient ink trapping. Several press variables can influence ink trap, some are controllable by the operator, such as press speed, or dryer settings on presses that have dryers in between press units. The ink tack may be afflicted past the outset press fountain solution or ink picture show thickness.

Some variables require changes that are beyond the operator's control, such as the ink tack specified in the offset ink. In this case, the ink vendor may be able alter the ink with additives or even switch to a different ink organization that has a different tack behavior. There are other variables that are more than difficult or impossible to change, at press fourth dimension, like the temperature at the press, and the substrate.

Print Contrast

Print Contrast

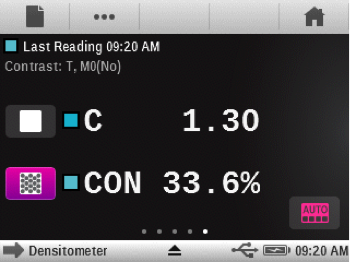

Shadow detail carries important information in many images. Print contrast values correlate well to the subjective evaluations of print quality, such as "flat" (depression print dissimilarity values) versus "jumps off the page" (high print contrast values). Compared to mid-tone dot proceeds values, which change with ink picture show thickness and therefore Density, high Impress Contrast values require both high density and sharp printing to maintain shadow detail.

This can be a valuable tool for printing fingerprinting to plant a density target that does not issue in reduced or unstable print contrast. It can be impacted past printing force per unit area, blankets, and ink additives. During production, it is often used as a guide for maintaining proper ink/water balance, and a deterioration of contrast over the run may point a demand for blanket washing.

ii - Spot Ink Process Control

Spot color density can be tricky. A traditional densitometer has congenital in filters that are optimized for each of the procedure ink colors. These filters are not optimal for all of the spot ink colors that yous may run. In fact, when measuring spot colors with this traditional filter set up, the densitometer may effort to select the filter automatically. Plus, the CMY filter choice could possibly change from ane measurement to the next, of the aforementioned ink. This volition provide wildly unlike numeric results.

Spot color density can be tricky. A traditional densitometer has congenital in filters that are optimized for each of the procedure ink colors. These filters are not optimal for all of the spot ink colors that yous may run. In fact, when measuring spot colors with this traditional filter set up, the densitometer may effort to select the filter automatically. Plus, the CMY filter choice could possibly change from ane measurement to the next, of the aforementioned ink. This volition provide wildly unlike numeric results.

And so, if yous need to measure the density of a spot ink color, you volition need a device that can measure a spot color at a spectral wavelength that is optimal for that ink. This will report the density based on the wavelength of light that is captivated the most. This wavelength will be identified with the standard symbol for wavelength, λ, which is called lambda.

Spot Color Tone Value (SCTV) is a relatively new method for calculating the tone value of your spot color inks (ISO 20654:2017). This method uses the spectral reflectance values in order to produce tone values between the paper (0%) and solid ink (100%). A traditional densitometer cannot provide this metric, for exactly the same reasons discussed earlier that it cannot provide spot color density. SCTV tone values are as well dissimilar than CMYK tone values. The math that is used for spot color tone values results in linear target values, so a 50% tint patch should measure as a l% tone value, or 0% TVI.

Exercise I Need a Densitometer?

What are the options from X-Rite? The eXact Basic will provide the capability of the traditional densitometer for the basic 4-color procedure density process command. For more avant-garde density functions and for spot colour density and tone value, you will demand the eXact Basic Plus. In the futurity, if you need to add together more control of color, in L*a*b*, or need to marshal your production to a print standard, like GRACoL, SWOP, Fogra etc., then your verbal densitometer can exist upgraded to an eXact Standard or verbal Advanced spectrophotometer.

Arrive impact to speak with a Colour Proficient about your specific needs.

Source: https://www.xrite.com/blog/densitometer-density-measurement

0 Response to "Silk Screen 4 Color Process Density Reading"

Post a Comment