How to Draw Isometric Pipe Drawings in Autocad

What is Piping Isometric Drawing?

Once the three-dimensional (3D) model has been established in piping design software like PDS, PDMS, or SP3D, Piping Designers/Engineers need to convey that information to the yard for fabrication and site for Construction. The transferred information must have to be sufficient for the fabricator with the vision of what is to be fabricated and how the piping should be connected with other elements, with exact dimensions and complete build/Bill of materials (BOM). This is where Piping Isometric Drawings play a magnificent role. So piping isometrics are directly used for the following situations:

- For Construction Services

- For marking up deviation during site modifications/ as-builting.

- For reference as Stress Analysis model built up and final stress mark up for updating stress requirements.

Piping isometrics indirectly helps to calculate many parameters required during project execution like:

- Inch Meter can be estimated as Length of pipe (in meter) x Size of pipe ( in inch )

- Inch Dia is calculated as Size of Pipe joint ( in inch) x No, of Joints

- Pipe Weight is calculated as π x diameter of the pipe (in m) x length (in m) x thickness (in mm) x density of pipe material. Density of CS = 7.85 g/cm3

- The volume of Water required for hydro testing is estimated as π x {Pipe ID (in meter)}² x Length of Pipe

- Insulation Area (in m²) can be found as [π(Pipe OD+ insulation thickness)] (all in meter) x Length of Pipe (in meter)

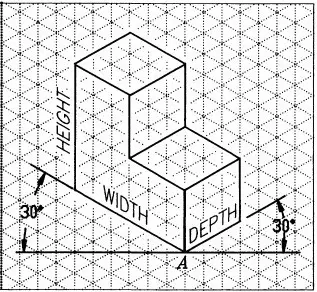

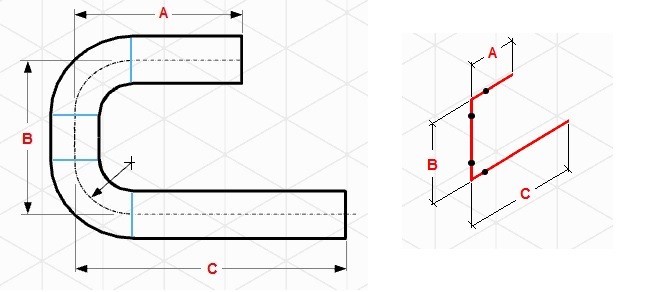

By definition, Isometric drawings are a pictorial representation that combines height-width-depth/length into a single view with 30 degrees from its horizontal plane as shown in the below attached image.

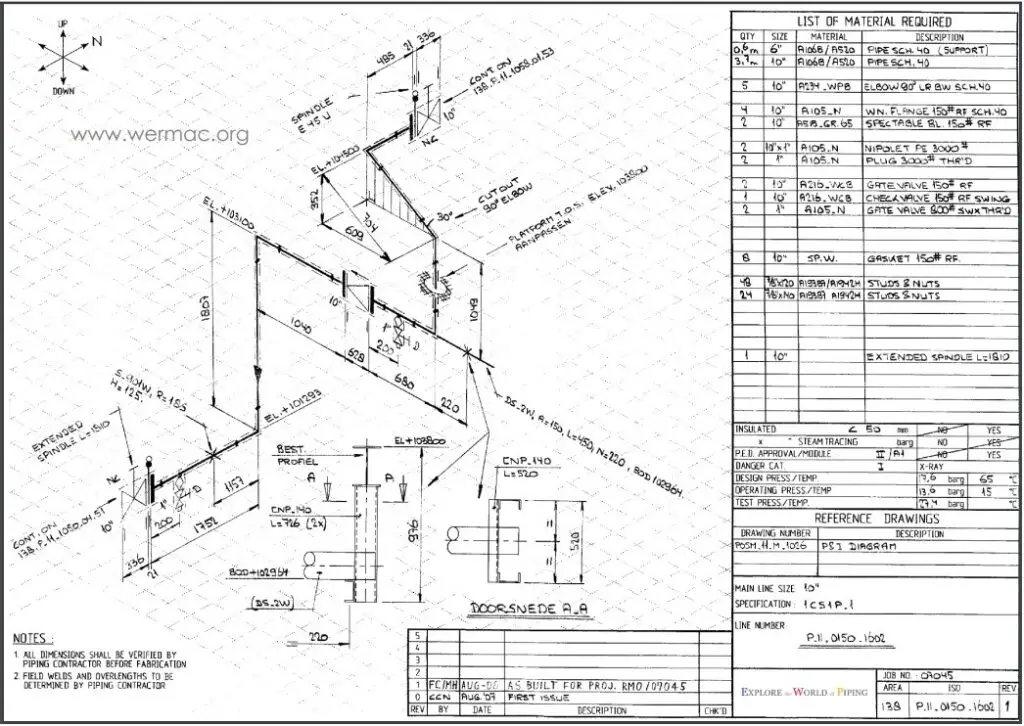

Features of Piping Isometric Drawing

Isometric Drawing is a two dimensional (2D) drawing that represents the 3D piping system. The important features are

- It is not drawn to the scale, but it is proportionate with exact dimensions represented.

- Pipes are drawn with a single line irrespective of the line sizes, as well as the other configurations such as reducers, flanges, and valves.

- pipes are shown in the same size. The actual sizes are notified in Bill of Material, tagging, call-out, or notes.

- A piping isometric drawing provides all the required information like:

- Pipe Line Number

- Continuation isometric number

- Flow direction

- Piping dimensions

- Piping joint types, weld types

- Flange and valve types

- Equipment connection details

- Piping and Component descriptions with size, quantity, and material codes

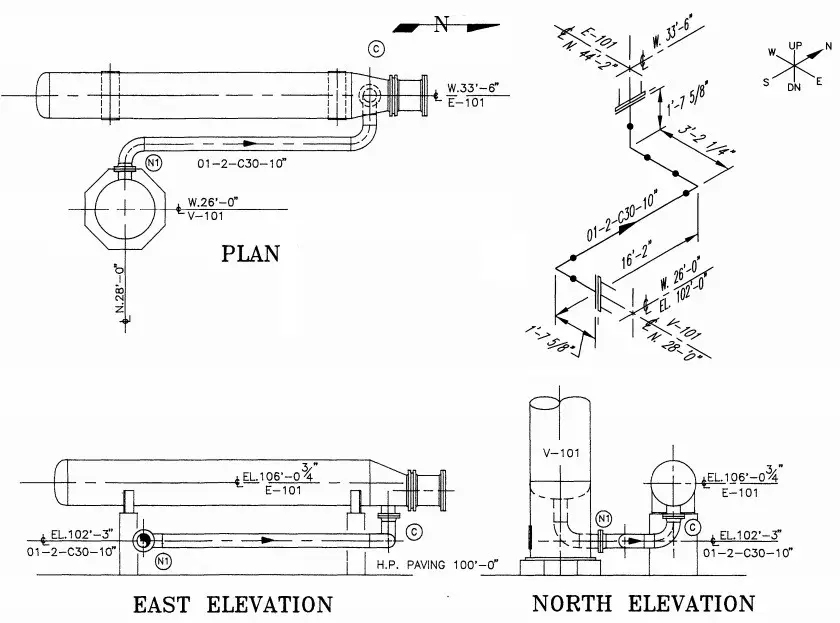

Piping Isometric drawings are popular because of their simplicity yet efficiency to convey complex information. The following figure gives an example of how one Isometric drawing can represent three orthographic drawings. That is just a simple piping drawing. Imagine complex design and yet orthographic drawings are used for construction, that is really a headache.

In earlier days, Isometric drawings were hand-drawn. With the innovation and advancement of the digital age, isometrics are drawn by AutoCAD/Microstation software. In recent days, the 3D models could automatically extract the Isometric with a single click of a mouse.

How to Read Piping Isometric Drawings?

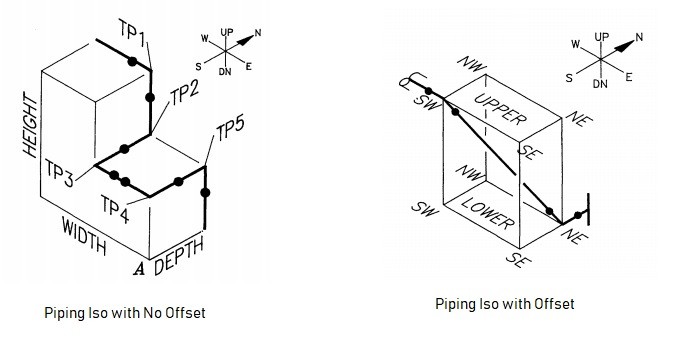

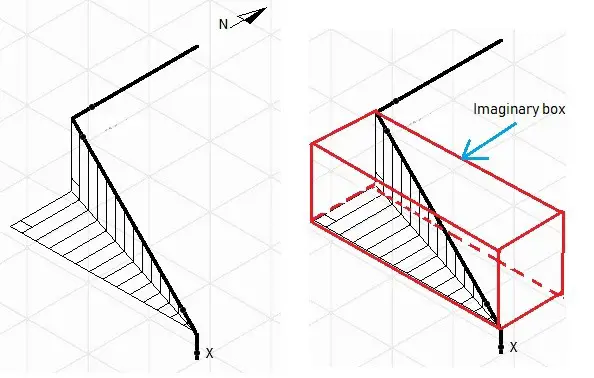

1. First, imagine that the piping system is built in a box. This basic imagination is required for the piping to have an offset. So, it will help you to imagine, how the piping configuration will look like as it travels.

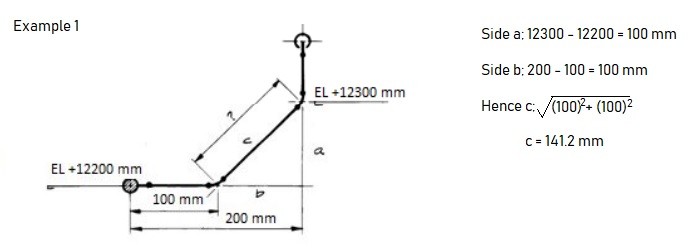

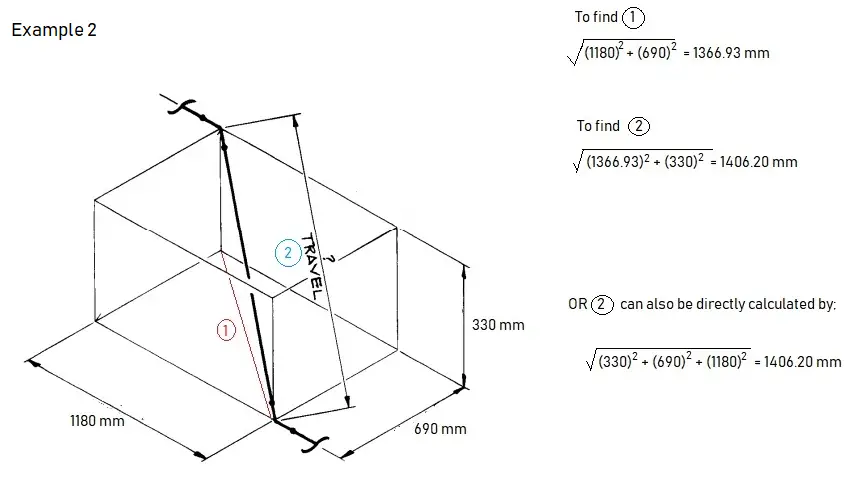

2.Offset happens when the pipe turns to any angle other than 90-degree or to accommodate odd nozzle's location or tie in point connections. A popular use is a 45-degree elbow and this is used extensively in piping design. In such cases, piping design may land on Northeast, Southeast, Northwest, or Southwest axes. In order to check the dimension of pipe length with offset, common Pythagoras's theorem and Trigonometric rule can be used. A sample calculation is shown below as a reference-

Example of length calculation in Piping Isometric

Example of offset

If you happened to have difficulties in reading the offset, try to draw the imaginary box. It could help you in having a better understanding of which axes the pipe travel and how the piping should look like. In the example given, take the flow from 'x', the pipe goes up; then up-northwest; then north. As you get along with Iso a lot, things will come naturally.

3. A North arrow is provided in all piping isometrics to inform the location of the piping system in piping/ general arrangement drawing.

4. The piping isometrics also hascoordinates & elevation detailed information to verify the exact length of pipe in horizontal and vertical axes respectively. The dimensions in Isometric drawings are measured from the pipe centreline and not from the outer diameter of the pipe (refer to the image attached below for reference).

With the advancement of technology, there could be minimum or even zero possibilities that the North arrow, coordinates, and elevation in Isometric would differ from the piping arrangement; hence the dimensions and MTO should match exactly if the source 3D model is the same.

However, It is always better to check and verify as there could be some issues with the modeling itself that may cause discrepancies in material and quantity. For example, if double piping is modeled by mistake, it will read the double quantity of material.

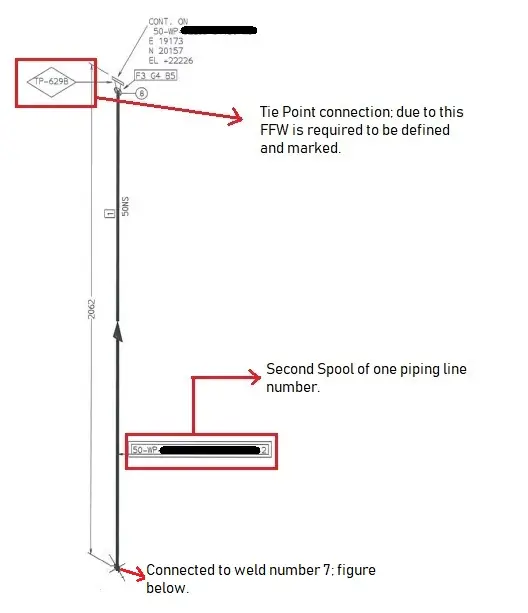

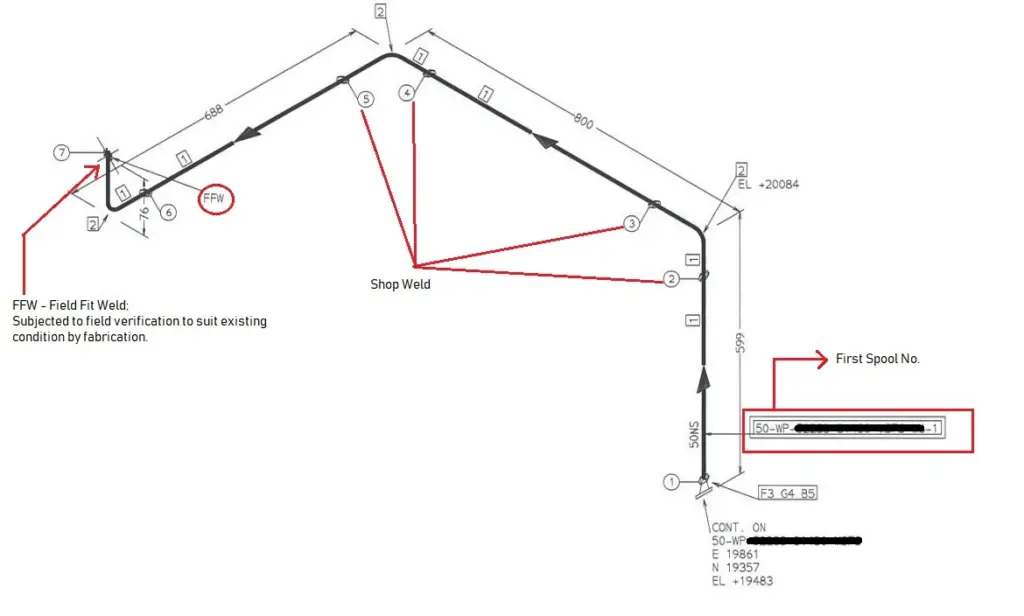

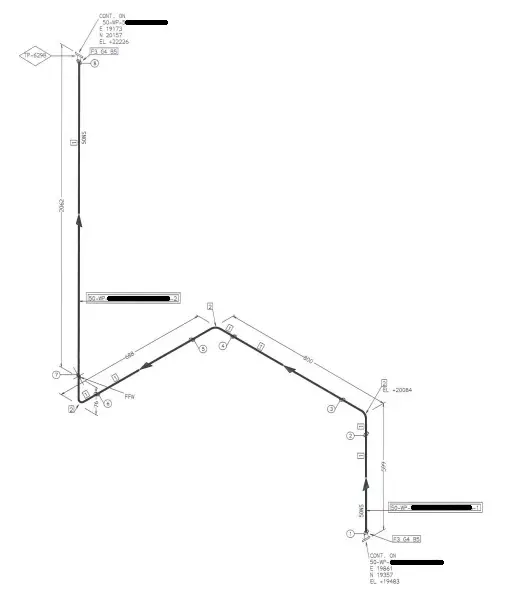

5. Isometric drawings also inform which piping should be constructed at the fabrication shop and which should be assembled at the construction/platform field itself. The complete piping system is separated into pieces that are transported to the site for erection. These small pipe pieces are termed piping spools. One sheet of Isometric drawing normally has few spools.

Every weld that is assembled between spools at the construction site is termed afield weld (FW). There is one more type of weld that is known as field-fit weld (FFW). This FFW is defined by the designer if he/she could foresee that the spool might require some adjustment before the final fit-up, so at the location of FFW has been marked, it will be given some pipe length tolerance (commonly 150-300mm). Usually, FFW will occur at the nozzle of equipment or tie-in locations.

The whole assembled piping will look like the following after it is assembled at the field.

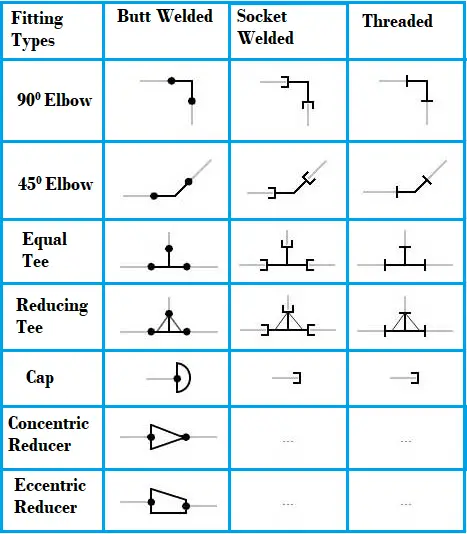

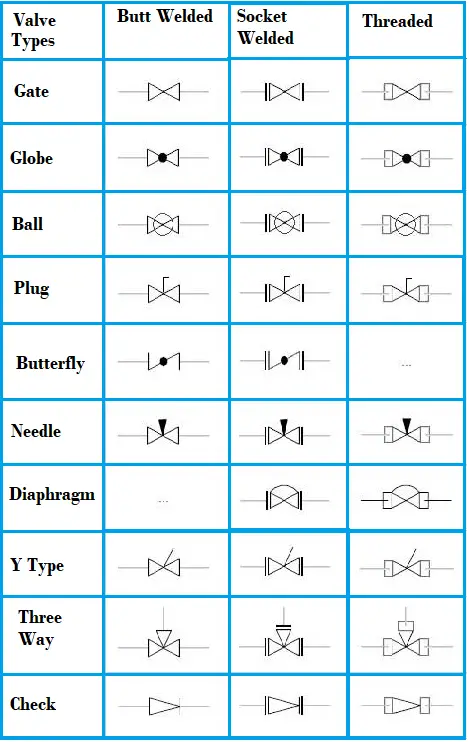

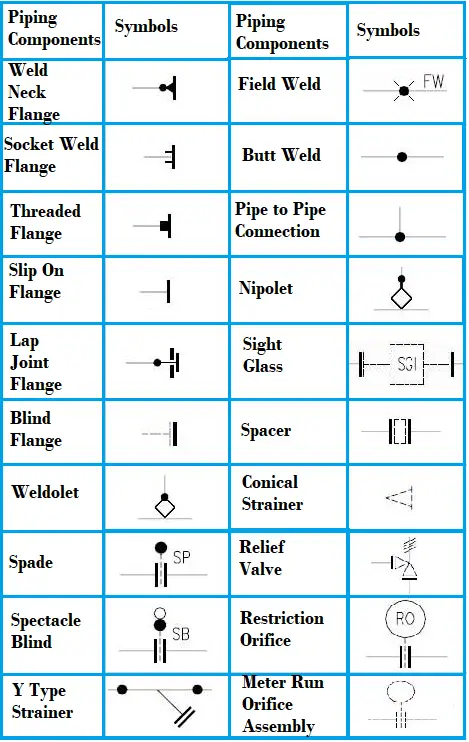

Piping isometric drawing symbols

For reading and understanding a piping isometric drawing, one should learn the piping isometric drawing symbols thoroughly. Usually, all these piping and pipeline drawing symbols are constant and does not vary much from one organization to the another. Knowing the piping drawing symbols will provide various information like:

- Type of Piping Joint: Piping and pipeline drawing symbols throw lights on the type of joint like Buttweld, socket weld, or Threaded.

- Type of piping Components: Isometric drawing piping symbols serves as a ready reference for type of fittings and components.

- Instrument items: Knowing the piping isometric symbols will help in recognizing the instrument and special piping items in the isometric.

- Equipment Connection: Equipment connected to a piping system is also understood with piping symbols.

- Knowing piping symbols for isometric drawing is useful in preparing MTO/BOM.

Commonly used piping isometric drawing symbols are shown below for reference purpose

Video Tutorial of Basics of Piping Isometric Drawing

The following video tutorial on the basics of piping isometric drawing will clarify some of your doubts.

Some more Resources for you…

Salient Points to check while reviewing Piping Isometric Drawings

Preparation of Piping Isometrics

Types of Piping Drawings

References

- Credit to other sources: svlele.com, wermac.org, pipingengineer.org, thepiping.com, spedweb.com, enggcyclopedia.com, rishabheng.com

- https://www.sciencedirect.com/topics/engineering/piping-isometric

Source: https://whatispiping.com/basic-piping-isometric-drawings/

0 Response to "How to Draw Isometric Pipe Drawings in Autocad"

Post a Comment